Unlocking Precision: Exploring the Realm of 5-Axis CNC Machining Services

By Bliss Machine, Inc. | April 2, 2024

In the intricate world of manufacturing, where precision is paramount and complexity knows no bounds, the realm of 5-axis CNC machining services reigns supreme. As a pinnacle of machining technology, 5-axis CNC (Computer Numerical Control) machining offers unparalleled capabilities that transcend traditional machining methods.

Let us delve into this cutting-edge realm and explore its intricacies, applications, and benefits.

Understanding the Fundamentals of 5-Axis CNC Machining

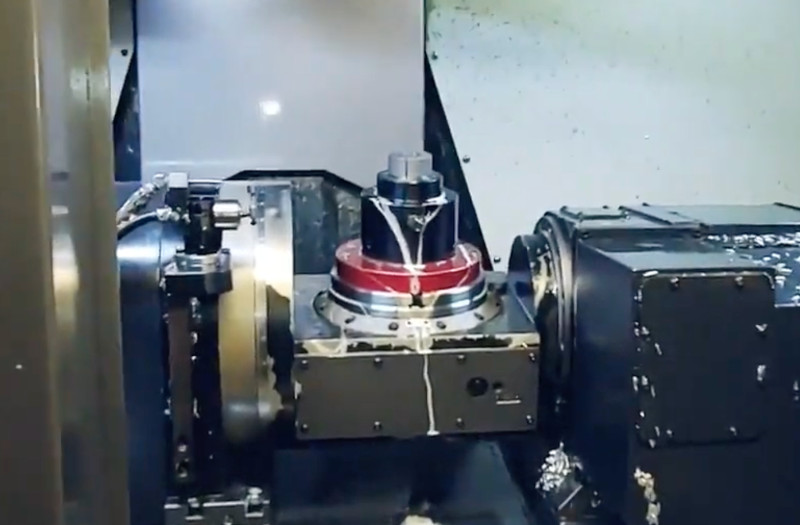

At its core, 5-axis CNC machining involves the utilization of advanced machining equipment capable of simultaneously moving a workpiece along five different axes: X, Y, Z, and two additional rotational axes, typically denoted as A and B. This multi-axis capability enables the fabrication of highly intricate and geometrically complex components with exceptional accuracy and efficiency. Unlike traditional 3-axis machining, which limits tool movement to three primary directions, 5-axis machining offers enhanced versatility, allowing for intricate geometries and contours to be machined with unprecedented precision.

Need More Information?

Give Us A Call!

Exploring the Versatility of 5-Axis CNC Machining

The versatility of 5-axis CNC machining knows no bounds, with applications spanning a myriad of industries, including aerospace, automotive, medical, and beyond. From intricate aerospace components with complex curves to precisely engineered medical implants, 5-axis machining caters to a diverse array of manufacturing needs. Its ability to machine complex geometries in a single setup minimizes production time, reduces material waste, and enhances overall efficiency, making it indispensable in modern manufacturing operations.

Unraveling the Benefits of 5-Axis CNC Machining Services

The advantages of 5-axis CNC machining services are manifold, offering manufacturers a competitive edge in today’s demanding market landscape. Enhanced precision, improved surface finish, and tighter tolerances are among the primary benefits of 5-axis machining. By reducing the need for multiple setups and tool changes, 5-axis machining streamlines the manufacturing process, resulting in faster turnaround times and reduced costs. Additionally, its ability to machine complex shapes and contours with ease opens up new possibilities for product design and innovation.

5-Axis CNC Machining Services

Navigating the Future of Manufacturing with 5-Axis CNC Machining

As we venture further into the era of advanced manufacturing, the significance of 5-axis CNC machining services becomes increasingly apparent. With advancements in machining technology and software capabilities, the future of manufacturing is poised for unprecedented growth and innovation. Embracing the capabilities of 5-axis CNC machining enables manufacturers to stay ahead of the curve, delivering superior quality, precision-engineered components that meet the demands of today’s discerning market.

Contact Bliss Machine, Inc. for 5-Axis CNC Machining Services

For manufacturers seeking to harness the power of 5-axis CNC machining, partnering with experienced and reputable machining service providers such as Bliss Machine, Inc. in Arade, New York. With a proven track record of delivering precision-engineered components across a diverse range of industries, trusted machining partners like [Company Name] offer unparalleled expertise, state-of-the-art equipment, and unwavering commitment to quality. By leveraging the capabilities of 5-axis CNC machining, manufacturers can embark on a journey of innovation, efficiency, and excellence in manufacturing.

If you’re ready to experience the unparalleled quality and reliability of Bliss Machine, Inc. take the next step by filling out our free quote request form today.