Exploring the Revolution: 5-Axis CNC Milling

By Bliss Machine, Inc. | March 11, 2024

In the realm of manufacturing, the advent of 5-axis CNC (Computer Numerical Control) milling stands as a beacon of innovation, radically transforming how industries approach the fabrication of complex and precision parts.

The Quintessence of 5-Axis CNC Milling

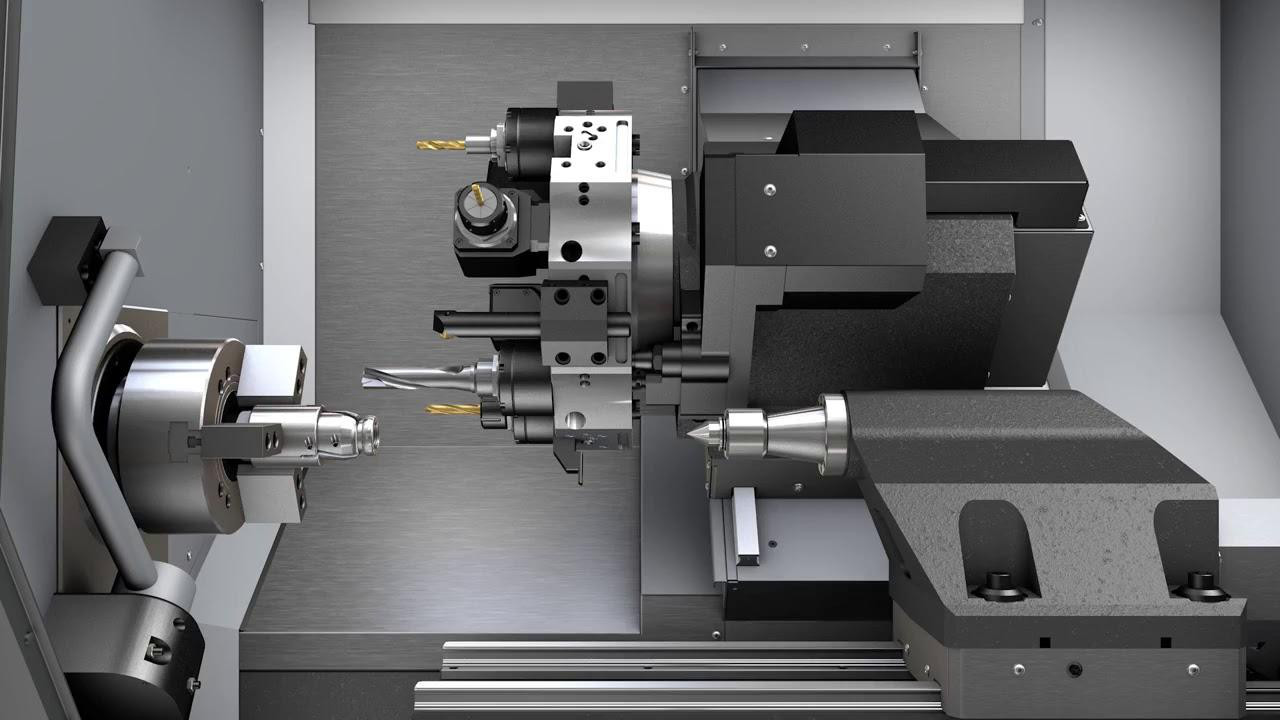

At its core, 5-axis CNC milling operates on the X, Y, Z axes, along with rotations on the A and B axes. This multidimensional approach not only enhances precision but also minimizes the need for multiple setups, a common necessity in conventional machining processes. The ability to manipulate the workpiece in five different axes simultaneously opens up a new world of possibilities, enabling the creation of geometrically complex components with ease.

Advantages of 5-Axis CNC Milling

5-axis CNC milling presents numerous benefits over traditional 3-axis systems. Its ability to access parts from virtually any direction in a single setup reduces the need for multiple setups, significantly cutting down production time and costs. This capability not only enhances productivity but also improves the quality of the final product by minimizing errors associated with repositioning.

Need More Information?

Give Us A Call!

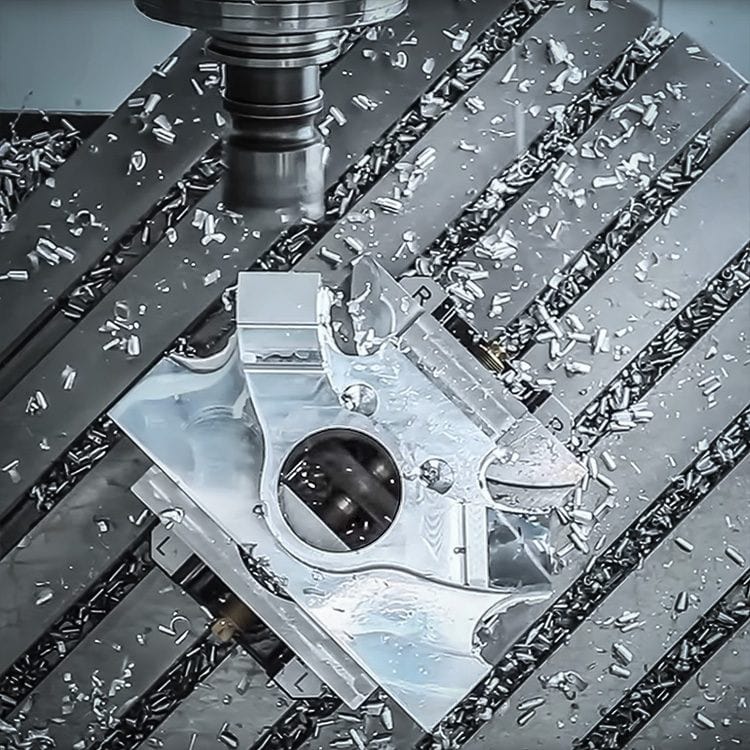

Complex Geometries with High Precision

The true strength of 5-axis CNC milling lies in its ability to produce complex and intricate parts with high precision. The additional axes allow for tighter tolerances and better surface finishes, which are critical in industries where the margin for error is minimal. Moreover, it enables the machining of challenging angles and undercuts without requiring custom tooling.

Reducing Material Waste

Efficiency in material use is another significant advantage. By allowing for more precise cutting paths, 5-axis CNC milling minimizes excess waste, making the process more sustainable and cost-effective. This precise material removal aligns with the growing emphasis on sustainability in manufacturing, reducing the environmental impact of production processes.

Challenges and Solutions

Despite its advantages, transitioning to 5-axis CNC milling comes with its challenges. The technology requires a higher initial investment in both equipment and training. Skilled operators and programmers are essential to navigate the complexities of 5-axis machining. However, the long-term benefits in efficiency, waste reduction, and product quality offer a compelling return on investment.

Future Prospects

The future of 5-axis CNC milling is promising, with continuous improvements in technology and software making it more accessible and efficient. Innovations in machine design, tooling, and control software are expanding its applications, making 5-axis CNC milling a pivotal technology in the future of manufacturing.

Contact Bliss Machine, Inc.

If you’re ready to experience the unparalleled quality and reliability of Bliss Machine, Inc. take the next step by filling out our free quote request form today.