How CNC Machining Improves Manufacturing Efficiency

By Bliss Machine, Inc. | June 20, 2024

In today’s fast-paced manufacturing environment, efficiency is crucial. Companies are constantly seeking ways to optimize production processes, reduce costs, and improve product quality. One of the most effective solutions is CNC (Computer Numerical Control) machining. Bliss Machine, a leader in precision manufacturing, utilizes CNC machining to significantly enhance manufacturing efficiency.

Here’s how CNC machining achieves this:

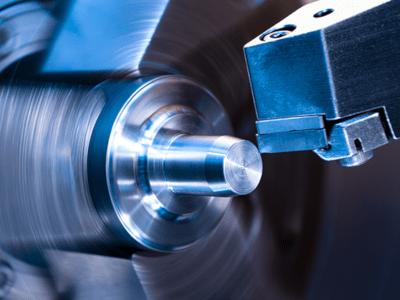

Precision and Consistency

CNC machines are renowned for their precision. Unlike manual machining, which can be prone to human error, CNC machining ensures that every part produced is an exact replica of the design specifications. This high level of precision minimizes waste and reduces the likelihood of defective parts. At Bliss Machine, we leverage the accuracy of CNC machines to maintain consistent quality across all our products, ensuring that each piece meets stringent standards.

Speed and Automation

One of the primary advantages of CNC machining is its ability to operate continuously without manual intervention. CNC machines can run 24/7, significantly increasing production capacity and reducing lead times. This automation allows Bliss Machine to complete large orders more quickly and efficiently than traditional machining methods. Moreover, CNC machines can be programmed to perform multiple operations simultaneously, further speeding up the manufacturing process.

Need More Information?

Give Us A Call!

Reduced Setup Time

Traditional machining often involves lengthy setup times for each new job, including manual adjustments and tooling changes. In contrast, CNC machines can quickly switch between tasks with minimal setup time. This flexibility allows Bliss Machine to handle a wide variety of projects without significant downtime, making our operations more agile and responsive to customer needs.

Enhanced Design Capabilities

CNC machining is compatible with advanced design software, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). These tools enable engineers to create highly complex and intricate designs that would be difficult or impossible to achieve with manual machining. At Bliss Machine, our skilled engineers utilize these capabilities to produce innovative and customized solutions for our clients, enhancing the overall value of our products.

Cost Efficiency

While the initial investment in CNC machinery can be substantial, the long-term cost savings are significant. CNC machines reduce labor costs by minimizing the need for skilled operators. Additionally, the precision and consistency of CNC machining reduce material waste, leading to cost savings on raw materials. Bliss Machine passes these savings on to our customers, offering high-quality products at competitive prices.

Improved Safety

Safety is a top priority in any manufacturing environment. CNC machining reduces the risk of workplace injuries by minimizing human involvement in the production process. Operators at Bliss Machine can program and monitor CNC machines from a safe distance, reducing the likelihood of accidents and ensuring a safer working environment.

Scalability

CNC machining is highly scalable, making it suitable for both small-scale and large-scale production runs. Whether it’s a single prototype or a large batch of parts, CNC machines can handle varying production volumes with ease. This scalability allows Bliss Machine to cater to a diverse range of industries and applications, providing tailored solutions to meet specific client requirements.

Continuous Improvement

At Bliss Machine, we are committed to continuous improvement. CNC machines provide valuable data and insights into the manufacturing process, allowing us to identify areas for optimization and implement process improvements. This data-driven approach ensures that we are constantly enhancing our efficiency and delivering better results for our customers.

Conclusion

CNC machining is a game-changer in the manufacturing industry, offering unparalleled precision, speed, and efficiency. At Bliss Machine, we harness the power of CNC technology to streamline our operations, reduce costs, and deliver superior products to our clients. As the manufacturing landscape continues to evolve, CNC machining will remain a vital tool in our quest for excellence and innovation.

If you’re ready to experience the unparalleled quality and reliability of Bliss Machine, Inc. take the next step by filling out our free quote request form today.