Top 5 Advantages of Using CNC Milling for Your Projects

By Bliss Machine, Inc. | July 10, 2024

In the world of manufacturing and precision engineering, CNC (Computer Numerical Control) milling has revolutionized the way we create intricate and high-quality components. From aerospace to automotive, and medical devices to consumer electronics, CNC milling plays a crucial role in producing parts with exceptional precision and consistency.

Here, we explore the top five advantages of using CNC milling for your projects and why it has become the go-to method for many industries.

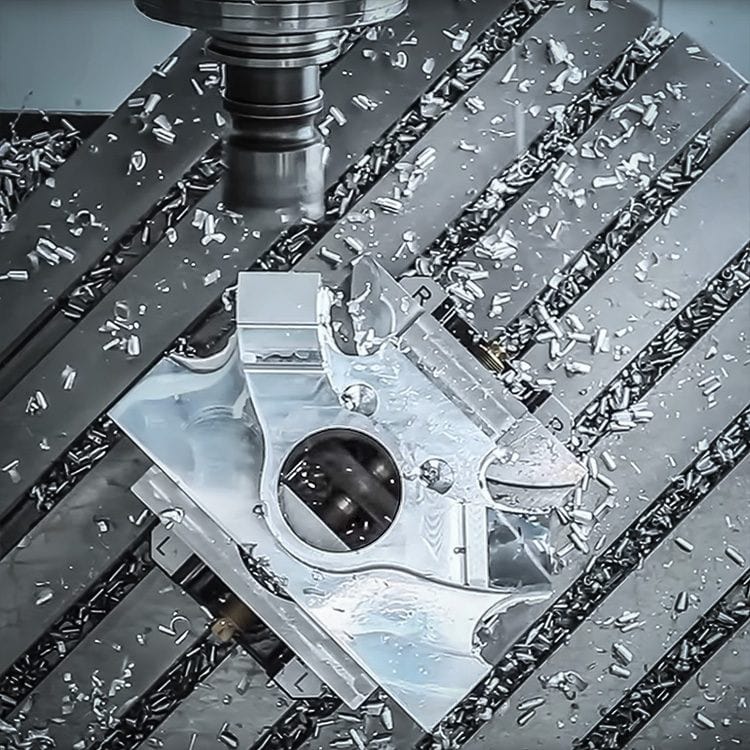

1. Unmatched Precision and Accuracy

One of the most significant advantages of CNC milling is its ability to produce parts with unparalleled precision and accuracy. Traditional manual milling relies heavily on the operator’s skill, which can introduce variability and human error. In contrast, CNC milling is driven by computer-aided design (CAD) files and computer-aided manufacturing (CAM) software, ensuring that every cut, angle, and hole is executed with exact specifications.

The precision of CNC milling is particularly vital for industries where even the smallest deviation can lead to significant issues, such as aerospace and medical device manufacturing. With CNC milling, you can achieve tolerances as tight as a few microns, ensuring that every part meets the highest standards of quality and performance.

2. Increased Efficiency and Productivity

CNC milling machines are designed to operate continuously and consistently without the need for frequent breaks or manual intervention. This capability translates to increased efficiency and productivity in the manufacturing process. CNC machines can run 24/7, producing parts faster than manual methods and reducing lead times.

Moreover, CNC milling allows for the automation of repetitive tasks, freeing up skilled operators to focus on more complex and value-added activities. This automation not only speeds up production but also minimizes the risk of errors and rework, further enhancing overall productivity.

Need More Information?

Give Us A Call!

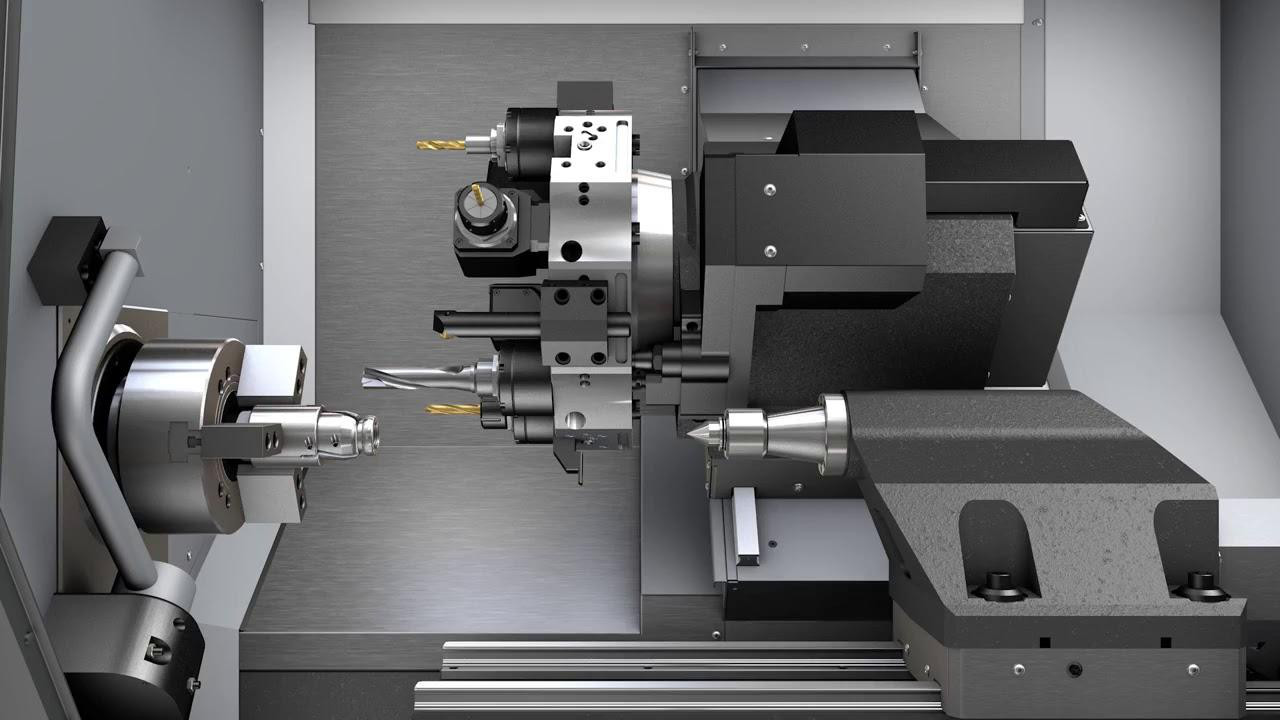

3. Versatility and Flexibility

CNC milling machines are incredibly versatile and capable of working with a wide range of materials, including metals, plastics, ceramics, and composites. This versatility makes CNC milling suitable for a diverse array of applications, from prototyping to large-scale production runs.

Additionally, CNC milling machines can perform multiple operations, such as drilling, tapping, and contouring, all within a single setup. This flexibility reduces the need for multiple machines and setups, streamlining the production process and reducing costs.

4. Consistent and Repeatable Results

Consistency is a critical factor in manufacturing, especially for industries that require large quantities of identical parts. CNC milling ensures that every part produced is an exact replica of the previous one, maintaining uniformity and consistency throughout the production run.

The repeatability of CNC milling is achieved through precise control of the machining parameters and the use of high-quality cutting tools. Once a CAD/CAM program is created, it can be reused for future production runs, ensuring that the same level of quality and precision is maintained over time.

5. Cost-Effectiveness

While the initial investment in CNC milling machines and software can be significant, the long-term cost savings are substantial. The efficiency, precision, and reduced labor costs associated with CNC milling translate to lower production costs and higher profit margins.

CNC milling also minimizes material waste by optimizing the cutting paths and using advanced nesting techniques. This reduction in waste not only lowers material costs but also contributes to more sustainable manufacturing practices.

Embracing CNC Milling Technology

CNC milling has transformed the manufacturing landscape, offering unparalleled advantages in precision, efficiency, versatility, consistency, and cost-effectiveness. By leveraging the power of CNC milling, businesses can achieve higher quality, faster production times, and greater profitability. Whether you’re working on a small-scale prototype or a large-scale production run, CNC milling provides the tools and capabilities to bring your projects to life with exceptional accuracy and efficiency. Embracing CNC milling technology is a strategic move that can elevate your manufacturing processes and position your business for long-term success.

If you’re ready to experience the unparalleled quality and reliability of Bliss Machine, Inc. take the next step by filling out our free quote request form today.