Exploring the Role of CNC Machining in Various Industries

By Bliss Machine, Inc. | February 14, 2024

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands out as a cornerstone technology that has transformed industries worldwide. From automotive to aerospace, healthcare to electronics, CNC machining plays a pivotal role in the production of intricate components and parts.

Let’s delve deeper into how CNC machining impacts different sectors and why it’s considered an indispensable tool for many industries.

Automotive Industry

In the automotive sector, precision and efficiency are paramount. CNC machining enables the production of complex automotive parts with tight tolerances, such as engine components, transmission parts, and chassis elements. With CNC machining, automotive manufacturers can achieve consistent quality and streamline their production processes, leading to enhanced performance and reliability in vehicles.

Aerospace Industry

Aerospace engineering demands components that are lightweight, durable, and able to withstand extreme conditions. CNC machining meets these requirements by producing aerospace-grade materials with exceptional precision and consistency. From turbine blades to structural components, CNC machines fabricate parts that adhere to stringent aerospace standards, ensuring the safety and reliability of aircraft and spacecraft.

Need More Information?

Give Us A Call!

Material Selection

With the digital blueprint and CNC program in hand, the next step is to select the appropriate raw material. This material can vary depending on the specific requirements of the component being manufactured. Common materials include metals like aluminum, steel, and titanium, as well as plastics and composites.

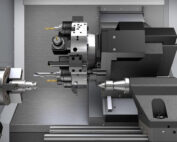

CNC Machining Process

Now comes the heart of the CNC machining process. The chosen raw material is secured in the CNC machine, which is equipped with the necessary cutting tools. The CNC program guides the machine’s movements with incredible precision, ensuring that the material is cut, shaped, and drilled according to the design specifications.

- CNC Swiss Turning: This technique is ideal for producing small, complex, and high-precision parts. It involves rotating the workpiece while the cutting tool moves along multiple axes.

- 5-Axis CNC Milling: 5-axis milling allows for the machining of intricate shapes and features from multiple angles. It offers unparalleled versatility and precision.

- CNC Milling: CNC milling machines use rotating cutting tools to remove material from the workpiece’s surface. It’s suitable for a wide range of part sizes and complexities.

- CNC Turning: CNC turning machines rotate the workpiece while a cutting tool shapes it into the desired form. It’s particularly effective for cylindrical and tubular components.

Healthcare Sector

In the healthcare industry, CNC machining plays a crucial role in the production of medical devices, implants, and instruments. From prosthetics to surgical tools, CNC technology enables the fabrication of intricate and customized medical components with high accuracy. This allows for advancements in patient care, surgical procedures, and medical diagnostics.

Electronics Manufacturing

The electronics industry relies heavily on CNC machining for the fabrication of circuit boards, enclosures, and precision components. With CNC technology, manufacturers can produce miniaturized electronic parts with intricate designs and tight tolerances. This contributes to the development of smaller, more efficient electronic devices, such as smartphones, laptops, and medical devices.

Defense and Military Applications

In defense and military applications, CNC machining is utilized for the production of mission-critical components, weaponry, and defense systems. From aircraft components to munitions, CNC technology ensures the precision and reliability required for military operations. Additionally, CNC machining allows for rapid prototyping and customization to meet the specific needs of defense applications.

Energy Sector

The energy industry relies on CNC machining for the production of components used in power generation, renewable energy, and oil and gas exploration. CNC technology enables the fabrication of turbine blades, valves, and drilling equipment with high precision and durability. This contributes to the efficiency and reliability of energy production systems worldwide.

Custom Manufacturing

Beyond specific industries, CNC machining offers opportunities for custom manufacturing across various sectors. Whether it’s creating prototypes, one-of-a-kind parts, or small-batch production runs, CNC technology provides the flexibility and precision needed for custom manufacturing projects. This enables businesses to bring their unique ideas to life and address niche market demands effectively.

Innovations in CNC Technology

As technology advances, so does CNC machining. Innovations such as multi-axis machining, additive manufacturing, and AI-driven automation are transforming the capabilities of CNC machines. These advancements allow for greater complexity, efficiency, and versatility in manufacturing processes, paving the way for new applications and industries to benefit from CNC technology.

Environmental Impact

CNC machining also offers environmental benefits by minimizing material waste and energy consumption compared to traditional manufacturing methods. The precision of CNC machines reduces the need for excess material, while efficient programming and tooling optimize production efficiency. As sustainability becomes increasingly important, CNC machining provides a greener alternative for manufacturing operations.

Global Impact

Lastly, CNC machining has a significant global impact, driving innovation, economic growth, and technological advancement across borders. From developed nations to emerging economies, CNC technology empowers manufacturers to compete on a global scale, fostering industrial growth and driving progress in various sectors worldwide.

At Bliss Machine, Inc., we are proud to be at the forefront of this technological revolution, delivering precision-engineered solutions to our clients across diverse sectors. With our state-of-the-art CNC machining capabilities and commitment to excellence, we strive to exceed expectations and deliver superior results with every project. If you’re ready to experience the unparalleled quality and reliability of Bliss Machine, we invite you to take the next step by filling out our request a quote form today.