CNC Milling vs. 3D Printing: Which is Better for Your Project?

By Bliss Machine, Inc. | August 28, 2024

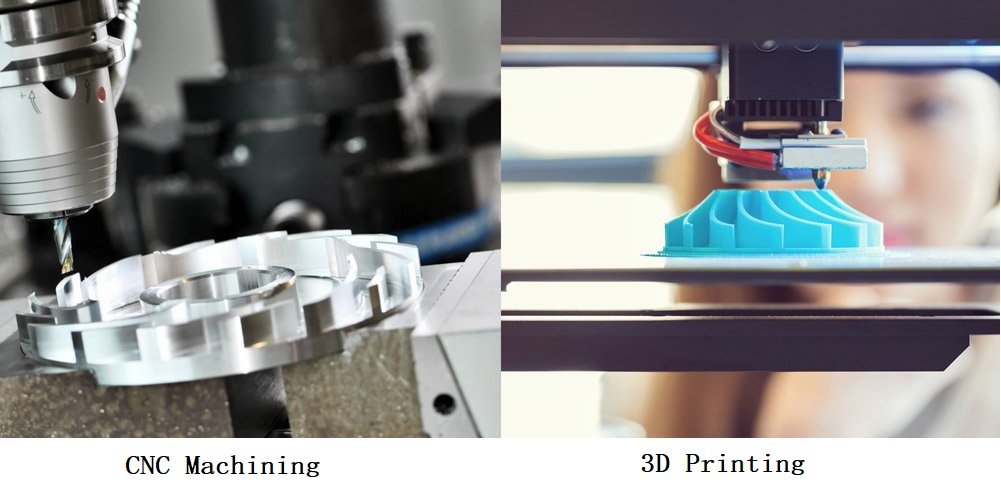

In the ever-evolving world of manufacturing, two technologies have emerged as frontrunners in the race for precision, efficiency, and versatility: CNC milling and 3D printing. Both offer unique advantages and can be the perfect solution depending on the specifics of your project. But how do you determine which one is right for you? Let’s dive into a comparison of CNC milling and 3D printing to help you make an informed decision.

Understanding CNC Milling

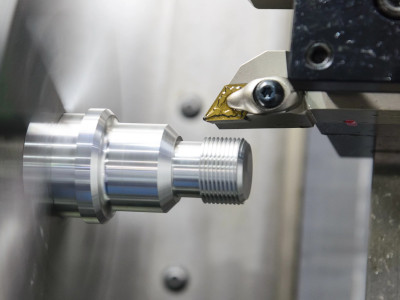

CNC (Computer Numerical Control) milling is a subtractive manufacturing process. This means it starts with a solid block of material, which is then precisely cut away using rotating tools to create the desired shape. CNC milling is renowned for its accuracy and ability to produce complex geometries with tight tolerances. It’s commonly used in industries such as aerospace, automotive, and medical, where precision and material strength are paramount.

The Strengths of CNC Milling

1.Material Versatility: CNC milling works with a wide range of materials, including metals, plastics, wood, and composites. This versatility makes it ideal for projects that require specific material properties, such as high strength or heat resistance.

2.High Precision and Tolerances: CNC milling can achieve extremely tight tolerances, making it perfect for components that need to fit together precisely or perform under demanding conditions.

3.Surface Finish: The subtractive nature of CNC milling allows for smooth surface finishes right off the machine, often requiring minimal post-processing.

4.Production Volume: CNC milling is well-suited for both low and high-volume production. Once the machine is set up, it can run continuously, producing identical parts with high repeatability.

Give Us A Call!

Understanding 3D Printing

3D printing, or additive manufacturing, is a process that builds objects layer by layer from a digital model. Unlike CNC milling, which removes material, 3D printing adds material, making it a highly flexible manufacturing method. 3D printing has gained popularity for its ability to quickly produce prototypes, complex geometries, and custom parts.

The Strengths of 3D Printing

1.Design Flexibility: 3D printing excels at creating complex, intricate designs that would be difficult or impossible to achieve with traditional methods. This makes it ideal for creative, custom, or highly detailed projects.

2.Rapid Prototyping: 3D printing allows for quick iterations of a design, enabling faster prototyping and testing. This is particularly valuable in product development cycles where time is critical.

3.Material Efficiency: Since 3D printing only uses the material needed to create the part, there is minimal waste. This can be a cost-effective option, especially for small batches or custom designs.

4.Low Setup Costs: For low-volume or one-off projects, 3D printing often has lower setup costs compared to CNC milling, making it more accessible for smaller businesses or individuals.

Choosing the Right Technology for Your Project

The decision between CNC milling and 3D printing ultimately comes down to the specific requirements of your project. If your project demands high precision, specific material properties, or high-volume production, CNC milling is likely the better choice. Its ability to work with a wide range of materials and achieve tight tolerances makes it indispensable for many industrial applications.

On the other hand, if your project involves complex geometries, rapid prototyping, or custom designs, 3D printing may be the way to go. Its flexibility and ability to produce intricate parts without the need for extensive tooling make it a powerful tool for innovation.

How do you determine which option is right for you?

CNC milling and 3D printing are both powerful manufacturing technologies, each with its own set of strengths. By carefully considering the demands of your project—whether it’s material choice, precision, production volume, or design complexity—you can choose the method that best aligns with your goals. In some cases, combining both technologies might even provide the optimal solution, leveraging the strengths of each to achieve the best possible results.

If you’re ready to experience the unparalleled quality and reliability of Bliss Machine, Inc. take the next step by filling out our free quote request form today.